FPSO Anna Nery (gas compression unit)

Client: Aragon AS

Year: 2020-2021

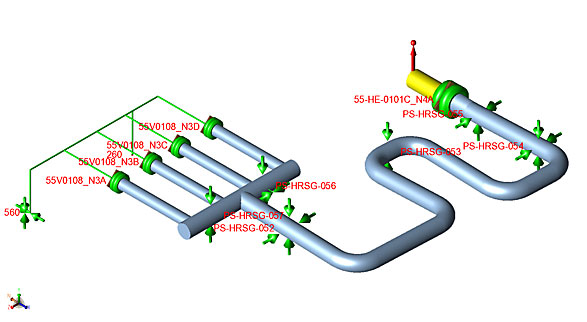

Pipe stress analyses are executed in accordance with recognized design standards, pipe specifications and customer requirements. We use Caesar II software to analyse e.g. design and operating temperatures and pressures, internal/external loads such as slug flow, wind, snow/ice, accelerations, external forces, imposed displacements and accidental cases with blast pressures and/or accidental heeling.

Pipe stress analyses are performed to document compliance with design standards, regulatory codes, customer specifications as well as determining support loads, support locations, equipment nozzle loads, pipe stresses and thermal displacements. We also implement pipe stress analyses/nozzle load analyses of rotation equipment such as pumps and compressors according to recognized standards.

Client: Aragon AS

Year: 2020-2021

Client: Aragon AS

Year: 2020-2021

Client: Wärtsilä Oil & Gas Systems AS

Year: 2019-2020

Client: Kanfa AS

Year: 2019-2020

Client: Kanfa AS

Year: 2019 – 2020

Client: Wärtsilä Oil & Gas Systems AS

Year: 2019

Client: Wärtsilä Oil & Gas Systems AS

Year: 2018 – 2019

Client: Kanfa Ingenium Process AS

Year: 2017 – 2018

Client: Wärtsilä Oil & Gas Systems AS

Year: 2017 – 2018

Client: Wärtsilä Oil & Gas Systems AS

Year: 2017 – 2018

Client: Kanfa Ingenium Process (part of KANFA GROUP)

Year: 2015 – 2016