Self-developed software makes projects more cost-effective

Focus Techouse Engineering has developed their own software for calculating pipe supports on process modules. The program calculations are carried out very efficiently to the benefit of Focus Techouse Engineering’s customers both in terms of time spent and project costs.

The pipe systems that are to be mounted on process modules and other similar installations are subjected to a number of different forces such as weight, pressure and temperature. The forces are also dependent on what the pipes contain and external forces like side loads from sea movements and wind during normal operations. These forces are calculated by the Pipe Stress Engineers at Focus Techouse Engineering’s offices in Norway or China.

“All the loads need to be calculated first. These calculations are used to input the data we use to calculate the strength of what we are constructing. In addition to normal forces, we must also take into consideration any accident scenarios. For example, we need to consider the extent of the loads the pipes will be exposed to during an explosion,“ explains our pipe support engineers.

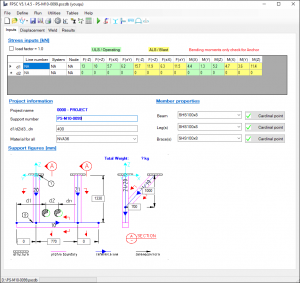

Pipe Support Calculation

The calculations can be done from anywhere across the globe by sending an input file to the Focus Techouse Engineering server. The calculation is performed and the answer is returned in 20 seconds.

Time-consuming processes curtailed

The first time the software was used on a real project was on the FPSO Dana Western Isles from 2015 to 2017. Many thousands of calculations had to be performed on the pipe supporters as part of this project. The good experiences gained from this project led to Focus Techouse Engineering opting to use their own calculation program in all their projects:

“We use this software for all our projects for Wärtsilä Oil & Gas Systems. The same applies to projects we have for Kanfa and other customers where this forms part of our tasks. Customers like Kanfa are experts in the actual process design, while Focus Techouse Engineering coordinate the equipment, escape routes, access and piping systems. We also create all the necessary documentation. We usually do all the structural design and place high focus on optimizing the design to save weight. When we find ways to save weight, the projects also become more cost-effective for our clients,“ Norr continues.

All the small elements in a pipe system such as frames, shoes, clamps, stoppers and sloping rods must be strengthened and documented. The calculations can be done from anywhere across the globe by sending an input file to the Focus Techouse Engineering server. The calculation is performed and the answer is returned in 20 seconds. On many of the projects there can be up to 1000 or more pipe supports, and on such projects the engineers at Focus Techouse Engineering can save as much as 1000 hours by using this software instead of making calculations on other types of systems.

Checked by DNV GL

DNV GL in London checked the software before it was used for calculating real projects. The control involved reviewing and verifying that the calculations in the model and the formulas used are correct. The control at DNV GL is not the same as an approval, but rather a control that confirms whether the program calculates correctly and that it conforms to internationally recognized standards.

“This provides extra security both for us who perform the calculations, and also for the customers who will own and operate the installations later,” says Norr.

“There are probably similar solutions to our system, but we have not yet seen any programs that are as effective as our own. We have been asked if we will sell the software we have developed, but have made a strategic decision to use this solution in order to gain a business advantage instead. We indirectly get more customers as a result of this solution, since our total package can be more cost-effective for the customer. We are experiencing high volumes of repeat business from our customers and we currently have so many assignments that we have had to turn business away. We are also looking to increase our workforce to cope with demand,“ Norr concludes.