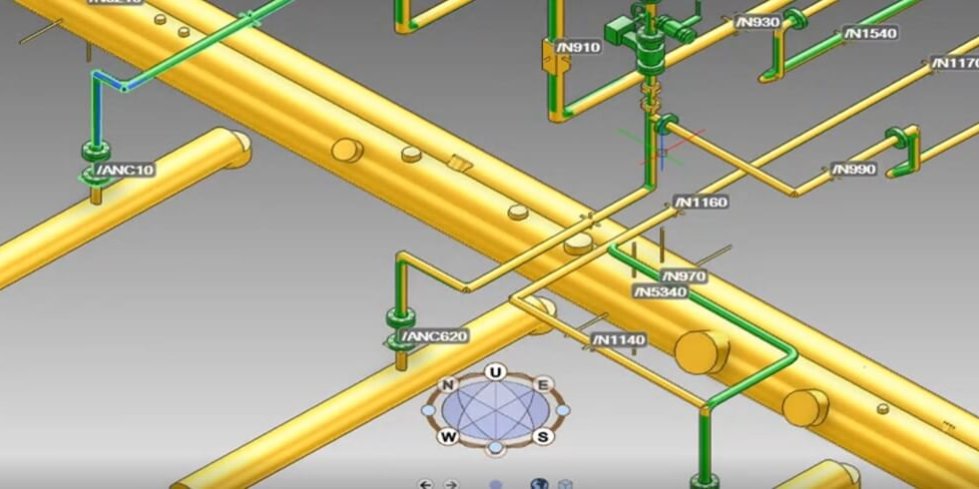

Image: Caesar II (in yellow) and E3d (in green) clearly points out discrepancies for further attention.

Working smarter by integrating stress and piping information in one 3D model!

Traditionally, pipe design and pipe stress are performed in two separate models. Ensuring that the two models are aligned is time-consuming.

Focus Techouse Engineering has made a tool to integrate design information between E3D and Caesar II, saving time, reducing the possibilities for errors, and freeing up the stress engineer to do actual stress design.

This enables us to include the pipe stress model directly in E3D, rather than comparing stress isometrics against the model. All design information can now be accessed and verified as required, using our in-house developed E3D toolbox. Designers no longer need to use temporary stress isometrics and do manual checks of large spreadsheets. This saves further time and reduces the risk of human errors.

Our Senior Pipe Stress Engineer, Bjørn Hjertø expresses with enthusiasm: “What we see here is an integrated information system, and I am now able to spend more time to focus on the actual design work.”

Idea and article by:

Gajanan R. Gaikwad, Senior Pipe Stress Engineer, Focus Techouse Engineering AS

Quanwu You (Karl), Senior Engineer Pipe Support LDD / IT Coordinator, Focus Techouse Engineering AS

Sondre Minnesjord, Senior Structural Analysis Engineer, Focus Techouse Engineering AS

Christer Hansen, Senior Piping & Layout Engineer, Focus Techouse Engineering AS